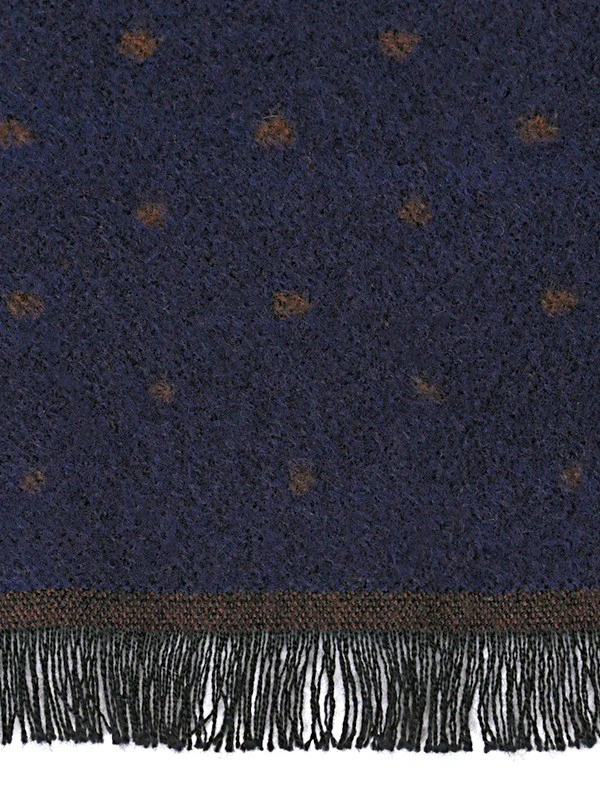

Silk woven pocket square is suit's standard configuration. It is made of woven polyester fabric, which is made of yarn-dyed art work. The yarn in different colors is interwoven in two directions. Weaving product will come out without being dyed later. Comparing to woven polyester pocket square, silk woven pocket square is higher grade.

|

Commodity |

Silk woven pocket square |

|

Material |

Woven silk |

|

Size |

21*21~30*30cm or Custom Size |

|

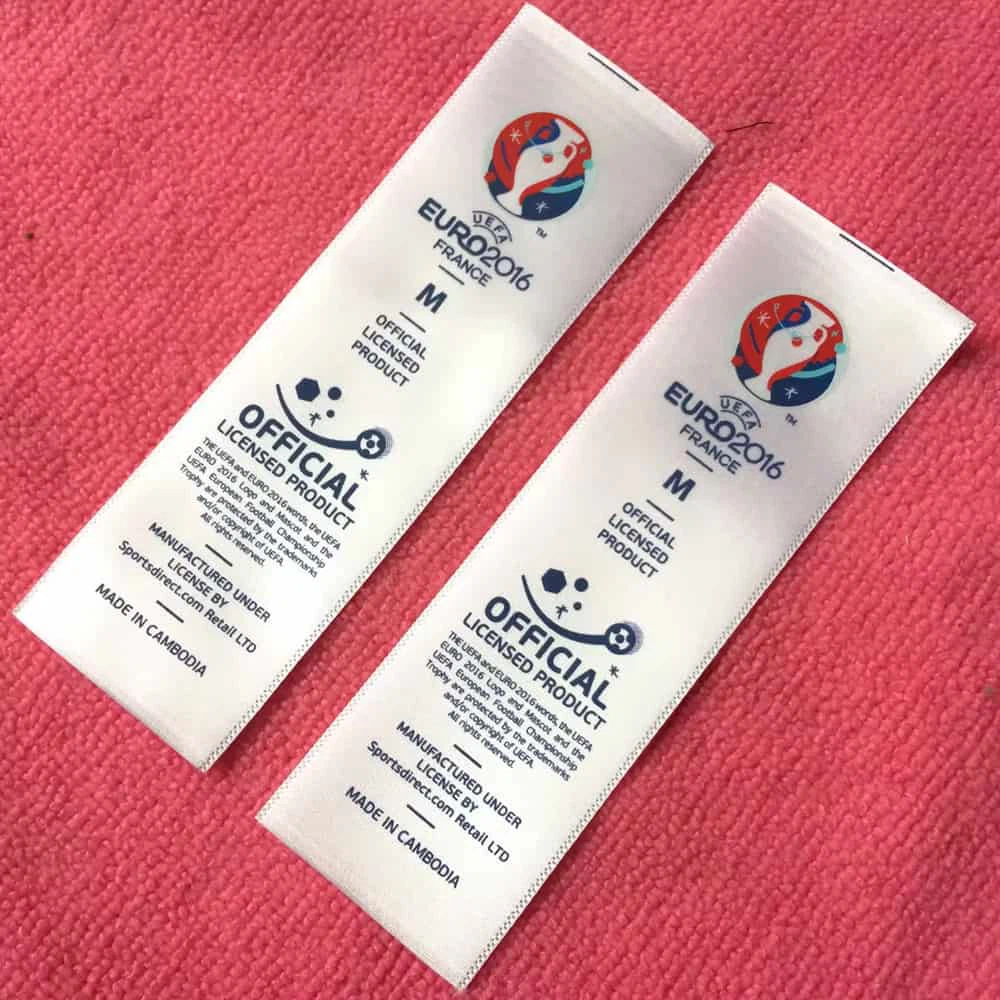

Label |

Customer's brand label and care label (need authorization). |

|

MOQ |

500pcs/color in same size. |

|

Packing |

1pc/pp bag |

|

Payment |

30%T/T. |

|

FOB |

Shanghai or Ningbo |

|

Sample time |

1week. |

|

Design |

Pick from our catalogues or customization. |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Why Choose YiLi |

|

|

1.25 years of production experience. |

2.Own factory building and equipments. |

|

3.ISO 9001, BSCI certification |

4.Professional design and color matching team. |

|

5. One-stop service of design, manufacture and export. |

6. Real manufacturers, not trading companies. |

|

7. Professional customization services. |

8. Quick proofing |

|

9. Thousands of designs are optional. |

10.Credit management. |

Q: How do you ensure material quality?

A: We strictly test raw materials for density, colorfastness, and composition before production. Only certified polyester fabrics meeting our standards are used.

Q: What controls are in place during production?

A: We monitor critical parameters (e.g., temperature, pressure, weaving speed) using automated systems (PLC/DCS) to ensure consistency. Statistical process control (SPC) tools detect deviations in real-time.

Q: How is the final product inspected?

A: Every pocket square undergoes:

Visual checks for defects like stains or uneven prints.

Size measurements to ensure dimensional accuracy.

Colorfastness tests for wash and light exposure resistance.

Q: Do you comply with international quality standards?

A: Yes, our factory is SGS-certified, and we adhere to global standards for chemical safety, physical performance, and ethical production.

Q: How do you handle defects or non-conforming products?

A: Defective units are isolated and traced to their production root cause. They are never shipped, and corrections are implemented immediately to prevent recurrence.

Q: Material Properties

A: Why is polyester a preferred material for pocket squares?

Polyester is chosen for its exceptional durability, wrinkle resistance, and color retention. It maintains its shape and vibrancy even after repeated use and washing, making it ideal for long-lasting accessories like pocket squares.

Q: Does polyester offer moisture-wicking properties?

A: Yes, polyester effectively wicks moisture away from the body, ensuring the pocket square remains dry and hygienic during extended wear. This makes it suitable for formal events where comfort is key.

Q: How does polyester compare to natural fibers in terms of maintenance?

A: Polyester requires minimal ironing due to its innate wrinkle resistance. It also retains dyes better than natural fibers, ensuring the design stays vibrant without fading.

Q: Is polyester environmentally friendly?

A: We offer recycled polyester options made from post-consumer waste (e.g., plastic bottles). This reduces environmental impact while maintaining the same high performance as virgin polyester.

Choose Your Custom Handkerchief Design Style

Flag

Floral

Geometric

Novelty

Paisley

Plaid

Plain

Polka-dots

Choose Your Custom Handkerchief Fabric

In our commitment to safeguarding the Earth and its inhabitants, we primarily offer natural materials such as silk, wool, cashmere, and blended biodegradable fabrics. Additionally, we provide recycled options like polyester crafted from plastic bottles and recycled cotton from old garments, alongside organic choices like organic cotton.

Quality Raw Materials

Premium yarn constitutes the foundation of exquisite silk Handkerchief.

Choose The Printing

Common printing techniques

Digital printing techniques

Digital printing techniques enable the transfer of intricate designs and images directly onto silk material. This method is efficient, with sample creation taking roughly 7-10 days and bulk production spanning between 15-20 days.

The advantage of digital printing includes its minimal requirement for quantities, starting as low as 10 pieces per design with potential for even smaller orders.

A notable limitation of this process is the depth of ink penetration, which often results in the reverse side exhibiting only 50-60% of the front's color intensity.

Two-sided digital printing

Two-sided digital printing represents a significant evolution in fabric printing techniques, allowing for the application of designs on both sides of a textile.

This advanced method ensures that ink thoroughly permeates the fabric, enabling identical or distinct patterns to be showcased on each side, essentially offering two scarves in a single piece.

The starting order quantity for double-sided digital printing is set at 100 pieces per design.

However, it's essential to consider that this process may involve extended production times and cost more than traditional single-sided digital printing.

screen printing

The key benefit of double-sided digital textile printing lies in its ability to produce crisp and clear imagery on both the outward-facing and reverse surfaces, ensuring sharp demarcation of patterns.

Whereas, with screen printing, a method preferred by celebrated labels such as Hermes, the ink deeply embeds into the fabric, creating a high-quality finish surpassing standard digital techniques.

Screen printing stands out for its long-lasting, vivid quality, and cost-efficiency for bulk orders.

It's worth noting, though, that screen printing stipulates a minimum order of 100 units per color, accompanied by a color screen fee of $20 USD per hue.

Choose Popular Sizes

|

Scarf Shape |

Popular Sizes |

| Square |

Small squares (Bandana-size): Around 22-24 inches square. Medium squares: Around 27-32 inches square. Large squares: 36+ inches square, sometimes worn as shawls or wraps. |

| Rectangle |

Narrow Scarves: Width: 6-12 inches, Length: 50-70 inches Perfect for a classic neck tie style or skinny scarf look. Medium Scarves:Width: 12-20 inches,Length: 60-80 inches This is a very common and versatile size, offering various styling options. Oversized Scarves/Wraps: Width: 20+ inches, Length: 70+ inches These offer more warmth and coverage, and can be styled like shawls. |

| Triangle | Small Triangle Scarf: Base: 30-40 inches, Height: 12-18 inches Worn close to the neck as a bandana or classic kerchief style. Medium Triangle Scarf: Base: 40-55 inches, Height: 18-25 inches Offers more versatility and fabric to work with for different styling options. Large Triangle Scarf: Base: 55+ inches, Height: 25+ inches Can be worn as a wrap or shawl for additional warmth or a more dramatic look. |

Choose Your Custom Square Edge

Choose Labels, Hangtags & Packages

Custom Pocket Square Label

Printed Labels

Printed labels exhibit distinct characteristics through their creation process, utilizing techniques such as digital, flexographic, and screen printing to ensure detailed and durable branding on a variety of materials.

Woven Labels

Woven labels are made by weaving text and designs directly into the fabric using threads, creating a high-quality, durable label that can feature intricate details and is commonly used for branding on clothing and other textiles.

scarf label hand sewing

Scarf label hand sewing stands out for its meticulous craftsmanship, as each label is individually stitched onto the scarf, offering a customizable value of the garment.

scarf label machine sewing

Machine sewing is characterized by its efficiency and uniformity, using automated machines allows for consistent stitching of labels onto scarves at a high speed.

Custom Pocket Square Hangtags

Smooth coated paper Hangtag

Smooth coated paper hangtags are crafted using high-grade paper with a coated finish. This coating can either be glossy or matte, enhancing the tactile experience and adding a visually appealing sheen or a sophisticated subtle glow to the tag.

Kraft paper Hangtag

Kraft paper hangtags boast a distinctive, rustic appeal that's quite popular with eco-friendly and artisan brands. Characterized by its natural brown color and textured feel, kraft paper gives a sense of organic quality and simplicity.

PVC Hangtag

PVC hangtags are known for their durability and versatility. Made from polyvinyl chloride, these tags are plastic-based and offer a water-resistant and tear-proof quality that paper tags cannot match. They have a smooth plastic surface that feels substantial and sturdy in hand.

Leather Hangtag

Leather hangtags exude a sense of luxury and sophisticated craftsmanship. Made from genuine or synthetic leather, these tags are durable and have a high-end tactile appeal. The material itself has a rich texture that can vary from smooth and polished to a more rugged and grainy feel.

Custom Pocket Square Packages

Custom Pocket Square Cases

FAQ

Material Properties

Q: Why is silk a premium material for pocket squares?

A: Silk offers a luxurious texture, natural sheen, and excellent drape, making it ideal for formal accessories. It's also highly absorbent, though it requires careful maintenance to preserve its quality.

Q: What types of silk are commonly used?

A: High-grade mulberry silk (e.g., 19MM 6A grade) is preferred for its superior luster and softness. Some factories also use 18-momme silk twill for its balance of structure and vibrancy in color reproduction.

Q: How does silk compare to polyester or cotton blends?

A: Pure silk is more delicate but offers unmatched elegance. Blends (e.g., silk-polyester) enhance durability and reduce cost but may sacrifice some aesthetic qualities.

Q: Is silk environmentally sustainable?

A: While conventional silk production has environmental impacts, some factories offer eco-friendly options like recycled silk or blends with organic materials.

Customization Services

Q: What customization options are available?

A: Factories typically offer full design freedom: logos, patterns, jacquard weaves, and multi-color prints. Custom sizes (e.g., 33×33 cm or 42×42 cm), packaging, and labels are also available.

Q: What is the typical MOQ and timeline?

A: MOQs start at 100 units per design, though some factories accept smaller trial orders. Production takes 7–20 days, depending on complexity.

Q: Do factories provide design support?

A: Yes, many offer design assistance to ensure artwork aligns with production feasibility and technical constraints.

Q: Can I request samples before bulk production?

A: Samples are available for approval, often at a cost (30–100), which may be deducted from bulk orders.

Q: Are hand-rolled edges available for a premium finish?

A: Yes, hand-rolled edges are a hallmark of high-end craftsmanship, ensuring elegance and durability.

Quality Control

Q: How do you ensure material quality?

A: Factories test raw silk for density, colorfastness, and composition. Only certified materials meeting standards (e.g., ISO, SGS) are used.

Q: What QC measures are applied during production?

A: Statistical Process Control (SPC) monitors weaving, printing, and hemming stages. Automated systems track parameters like temperature and pressure to ensure consistency.

Q: How are finished products inspected?

A: Each pocket square undergoes:

Visual checks for stains, uneven prints, or defects. Size and hem consistency verification. Colorfastness tests for wash and light exposure resistance.

Q: Do you comply with international quality standards?

A: Yes, factories adhere to AQL (Acceptable Quality Limit) standards (e.g., ISO 2859-1) for sampling inspections, ensuring defects are within acceptable limits.

Q: How are defects handled?

A: Defective units are isolated and analyzed for root causes. Corrective actions are implemented to prevent recurrence.