Raw Material Characteristics

Premium suit craftsmanship begins with foundational materials: Virgin wool, silk-blend linings, and ethically sourced cotton pocketing form our core fabrics. Wool fibers (typically 100-180g weight) deliver breathability and drape, while reinforced horse canvas and horn buttons ensure structural integrity.

Sustainability

Our suits champion circular fashion: Traceable Merino wool from regenerative farms, buttons from renewable corozo nuts, and linings from 68% recycled PET bottles. Zero-waste patterning minimizes offcuts, while waterless dyeing reduces consumption by 90%. Garments feature fully biodegradable components, with carbon-neutral shipping globally.

Usage Scenarios

Designed for modern versatility: Structured double-breasted cuts with peak lapels command boardrooms; unlined linen-blend blazers transition to summer weddings. Five-pocket travel suits feature stretch wool for airport-to-meeting readiness, while tuxedos with satin shawl collars elevate galas.

Texture

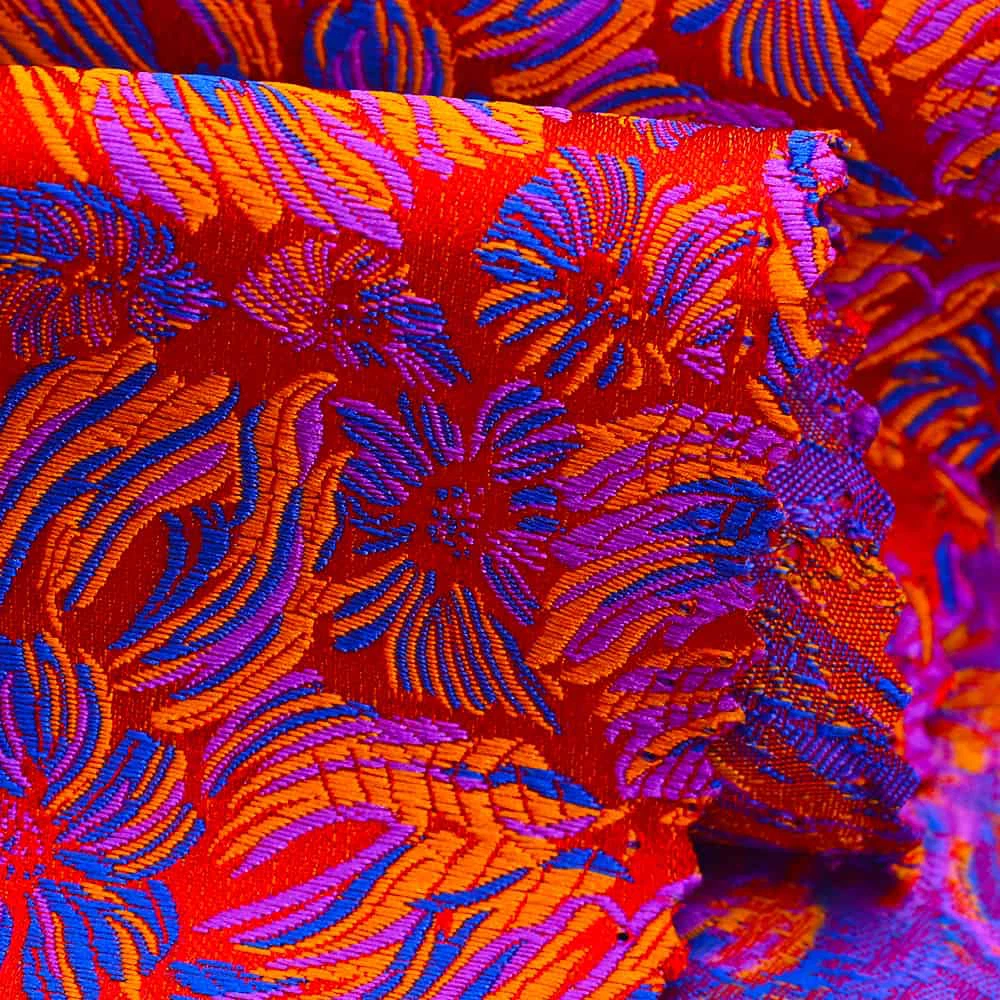

Texture defines character: Crisp fresco weaves offer grain-like tactility ideal for summer; high-twist flannels provide soft, brushed warmth in winter. Silk-mohair blends create luminous sheen for eveningwear, while unfinished hopsack fabrics showcase nubby dimensionality.

Application Fields of Suits

Corporate Uniforms

Tailored suits reinforce corporate ethos and team cohesion through structured silhouettes, brand-aligned colors, and wrinkle-resistant fabrics for daily professionalism.

Event Attire

Custom-tuxedos and brocade blazers serve weddings/galas with ceremonial gravitas, balancing visual harmony, thematic colors, and guest comfort.

Retail Branding

Staff uniforms as tactile branding: Luxury fabrics and signature cuts (e.g., peak-lapels) elevate boutique identity while ensuring day-long mobility.

Film Production

Period-accurate military uniforms or sci-fi suits project narrative authenticity via meticulous fabric aging, era-specific tailoring, and character-defining details.

Suit Customization Options

Customized Material

Wool

Cotton

Linen

Silk

Polyester

Velvet

Poly-Viscose Blend

Recycled Polyester

Collar Design

Notch Lapel

Shawl Lapel

Peak Lapel

Basic Suit Style

Continental Cut

Japanese Cut

Korean Cut

American Cut

| Cut | Shoulder | Waist | Hem | Formality |

|---|---|---|---|---|

| Continental | Structured | Tapered | Narrow | High |

| Japanese (H-Line) | Natural | Straight | Straight | Moderate |

| Korean | Narrow | Tight | Slim | Low-Casual |

| American | Unpadded | Loose | Full | Casual |

Button Configuration

Single-Breasted Suits

Distinguished by a single vertical column of buttons (typically 1 to 3), single-breasted jackets feature a modest front overlap (2–3 inches/5–7.6 cm) that creates a clean, elongated V-shaped silhouette. This versatile design accommodates all body types while offering practical advantages: swift donning/doffing, cost-efficient fabric consumption (~15% less than double-breasted), and seamless adaptability from business (2-button) to formal (1-button) settings. Its slimming effect and simple alteration requirements make it the default choice for corporate uniforms and daily wear, particularly in warmer climates due to reduced fabric layers.

Double-Breasted Suits

Characterized by parallel columns of buttons (typically 4×2 or 6×2 configurations) and a wide front overlap (4–6 inches/10–15 cm), double-breasted jackets construct a powerful triangular silhouette that enhances masculine proportions: broadened shoulders, cinched waist, and vertical line emphasis. Rooted in naval military tailoring, this design mandates all functional buttons to remain fastened, providing superior insulation (+3°C warmth) and projecting authority. Preferred for boardrooms, formal events, and cold-weather wear, it requires precision tailoring (especially across the chest) but delivers unmatched visual impact for executive roles and luxury hospitality uniforms.

Custom Suit Sizes

| International Sizes | US/UK Sizes | European Sizes | Suit bust(inch) | Suit bust(cm) | Suit waist(inch) | Suit waist(cm) |

|---|---|---|---|---|---|---|

| XS | 30-32 | 40-42 | 32-35 | 81-89 | 28.5-29.5 | 72-75 |

| S | 34-36 | 44-46 | 35-37.5 | 89-95 | 29-32 | 74-81 |

| M | 38-40 | 48-50 | 37.5-41 | 95-104 | 32-35 | 81-89 |

| L | 40-42 | 50-52 | 41-44 | 104-112 | 35-38 | 89-96 |

| XL | 44-46 | 54-56 | 44-48.5 | 112-123 | 38-43 | 96-109 |

| XXL | 48-50 | 58-60 | 48.5-53.5 | 123-136 | 43-47.5 | 109-121 |

Jacquard Suit Reference Measurements (Style H2025.04.27)

* Units in centimeters. Red highlights indicate key sizing transitions

| Measurement | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 | 62 |

|---|---|---|---|---|---|---|---|---|---|

| Back Center Length | 70 | 71 | 72 | 73 | 74 | 75 | 76 | 77 | 78 |

| Shoulder Width | 42.4 | 43.6 | 44.8 | 46.0 | 47.2 | 48.4 | 49.6 | 50.8 | 52.0 |

| Back Width | 39.4 | 40.6 | 41.8 | 43.0 | 44.2 | 45.4 | 46.6 | 47.8 | 49.0 |

| Chest (1/2 Circumference) | 48.0 | 50.0 | 52.0 | 54.0 | 56.0 | 58.0 | 60.0 | 62.0 | 64.0 |

| Waist (1/2 Circumference) | 42.5 | 44.5 | 46.5 | 48.5 | 50.5 | 52.5 | 54.5 | 56.5 | 58.5 |

| Bottom Hem (1/2 Circumference) | 49.5 | 51.5 | 53.5 | 55.5 | 57.5 | 59.5 | 61.5 | 63.5 | 65.5 |

| Sleeve Length | 62.0 | 62.5 | 63.0 | 63.5 | 64.0 | 64.5 | 65.0 | 65.5 | 66.0 |

| Upper Sleeve Width | 17.7 | 18.3 | 18.9 | 19.5 | 20.1 | 21.3 | 21.9 | 22.5 | - |

| Cuff Width | 12.6 | 12.9 | 13.2 | 13.5 | 13.8 | 14.1 | 14.4 | 14.7 | 15.0 |

Accent Measurements

- Chest Pocket:9.5×2 to 11×2 cm

- Welt Pocket Flap:15×4.2 to 16×4.2 cm

- Inside Pocket:13 cm (Length)

- Pen Pocket:7×2 cm

- Card Pocket:19 cm (Length)

- Notch Lapel Width:6 cm

- Peak Lapel Width:7 cm

Suits Packing

Our Suit support customers' customized packaging to meet personalized needs. We provide various hooks and tag stickers to make the retail packaging more beautiful. We can also use various gift boxes to package your ties to enhance your brand value.

We try to reduce the packaging volume of our products to ensure transportation safety and save freight. Our suit packaging consists of outer boxes, waterproof bags, and suit packaging, which can protect our products from damage during transportation.

| products IMG |

|

|

|

| Suit Style | Notch Lapel | Shawl Lapel | Peak Lapel |

| suit size(cm) | 150*8 | 50*9 | 47*6 |

| Suit Quantity/Carton | 20 | 20 | 20 |

| carton size(cm) | 79*53*18 | 79*53*18 | 79*53*18 |

| Carton net weight | 13.8 | 13.5 | 13.9 |

| Carton gross weight | 15 | 15 | 15 |

Hot Products According to Our Clients Feedback

YiLi not only produces jacquard fabric. We also customize neckties, bow ties, pocket squares, women's silk scarves, and other products that customers love. Here are some of our products that customers love.

Estimated Project Cost

To ensure that your business will have enough profit, it is essential to determine the overall cost of your project before officially starting it. Here are some of the expenses that you can expect to incur during the project:

Design Fee

If you need us to customize your tie design, we charge a fee of USD 20 per style. You don't have to worry about your design being leaked. If you use our design, we don't charge any design fee.

Product Cost

It depends on the style, material, design, quantity, and other factors of your customized tie. Our ties offer a super low MOQ: 50 pcs/design, and you can test your project for very little money.

Transportation Cost

Shipping costs depend on the quantity of ties your order and your region.

Tariff

Almost all countries will charge tariffs for imported products, and the charges differ in different countries. You can consult our sales representatives if you don't know how much your country will charge.

Sample fee

We can provide free Material samples if you want to check our product quality. You only pay for shipping. If you need customized samples, we will also charge a design fee.

Other costs

In some special cases, a special fee will be charged. If you ask a third party to inspect the goods. Or you need to enjoy government tariff relief, you need to provide a certificate of origin, etc.

If you want to start working in the tie industry, I suggest you check out our article - Is it a big investment to start a necktie business?

Estimated manufacturing and shipping times

Before starting a project, you will have a project schedule. Knowing how long the tie-making process will take will keep your plan on track. Below is the time it takes for our tie-making mass production.

Step 1 - Sample Production

Including tie design, fabric production, tie making, tie inspection, and other steps. With our excellent and complete team, we only need five days to complete the production of custom tie samples.

Step 2 - Sample Confirmation

Including international transportation, customer inspection, communication modification, etc.

This process mainly takes time for international transportation and customer confirmation, which takes about 10~15 days.

Step 3 - Mass Production

Including fabric production, tie production, inspection, and packaging.

The mass production time is between 18~22 days; the specific time is related to the quantity you ordered.

Step 4- International Shipping

Including customs declaration, international transportation, customs clearance, local distribution, etc.

Shipping time is related to the shipping method; by sea is about 30 days, and Express and Air freight are about 10~15 days.

FAQ

Q: What is Foreign Trade-Express?

A: Foreign Trade Express is a one-stop intelligent foreign trade network marketing SaaS system platform.

Q: What's the typical minimum order quantity (MOQ) for suits?

A: MOQs vary significantly (e.g., 300-1000+ units per style/color/size). Key factors include:

Fabric: Requires meeting mill minimums.

Trims: Lining, buttons, thread volumes.

Production Setup: Pattern grading, marker making, line configuration costs.

Size & Color Breakdown: Complexity increases cost.

(Negotiation possible for very simple orders)

Q: How long does production take from order confirmation to shipment?

A: Standard lead time is 8-14 weeks, subject to:

Current Workload: Factory capacity utilization.

Order Complexity: Fabric sourcing, design details, number of sizes/colors.

Approvals: Sample approval speed.

Fabric & Trim Availability: Sourcing lead times (esp. critical for special fabrics).

(Urgent orders possible at premium cost & with confirmed material stock)

Q: What fabrics are most common for factory-produced suits?

A: Primarily machine-woven fabrics for cost/availability:

Wools/Wool Blends: Worsted wools, wool/polyester.

Polyester/Viscose Blends: Durable, cost-effective.

Cotton/Cotton Blends: Linen blends for warmer weather.

(Factories optimize for bulk availability and ease of industrial processing)

Q: What size ranges do you typically offer?

A: Factories produce standardized size scales:

Regional Sizing: US (e.g., 36-50 Regular), EU (e.g., 46-58), UK, etc.

Standard Fits: Regular, Slim, Contemporary/Modern (varies by factory specs).

(Customized scales possible but significantly increase MOQ & cost for grading/pattern setup)

Q: Can you make suits based on my brand's existing samples or designs?

A: Yes, standard factory service:

Tech Pack Essential: Requires detailed tech pack (specifications sheet).

Existing Sample: Can reverse engineer (less ideal than tech pack).

Development Process: Prototype sampling (cost applies), then approval.

(Provide comprehensive specs upfront for best accuracy/speed)

Q: What quality control measures do you have?

A: Multi-stage QC integrated:

In-Line QC: Operators + supervisors check pieces during sewing.

Mid-Production Audit: Sampling at critical stages.

Final Pre-Shipment Inspection (PSI): AQL standards per client contract (e.g., AQL 2.5). Factory QC team handles; clients may arrange independent inspection.

(Defect thresholds defined per international AQL standards)

Q: What customizations are feasible within bulk production?

A: "Bespoke" is cost-prohibitive; factories offer limited customization options:

Lining Choices: Different colors/prints (bemberg standard).

Button Types/Hardware: Plastic, corozo, horn-look options.

Functional Details: Working cuff buttons, ticket pocket, pick-stitching (depends on MOQ/complexity).

Simple Labeling: Brand labels, care labels.

(Radical design changes usually require larger MOQ to justify pattern/press setup)

Q: Why might suits wrinkle quickly after wear?

A: Primary causes:

Fabric Composition: High polyester/low wool content blends wrinkle more easily. Natural fibers have better recovery.

Fabric Quality: Tightness of weave/thread quality impacts resilience.

Industry Construction: Fusing, machine pressing & efficiency focus over traditional canvassing impact drape/wrinkle resistance.

(Factory bulk suits use fusible interfacing; full/half canvas requires significantly higher MOQ/pricing)

Q: Can I buy a single suit directly from the factory?

A: Generally no. Factories are B2B wholesale, focusing on bulk orders:

MOQ Requirement.

Packaging/Handling: Single units are logistically inefficient.

Sales Channels: Brands/retailers handle direct consumer sales.

(Inquire about potential off-price bulk sales or wholesale distributors)

Q: What certifications does your factory hold?

A: Common industry compliance standards include:

Social: BSCI, Sedex, WRAP, amfori BSCI (monitor labor practices).

Quality: ISO 9001.

Environmental/Safety: ISO 14001, ISO 45001 (varies).

(Specify required certifications during inquiry)

Q: What are your payment terms for new clients?

A: Common terms for wholesale orders:

Initial Orders: T/T with deposit (e.g., 30-50%) pre-production, balance pre-shipment.

Established Clients: Possible flexibility (e.g., T/T 30 days post-shipment). L/C also common.

(Specifics negotiated per relationship & order risk assessment)

Q: What is your sampling process/cost?

A: Standard development stages:

Prototype Sample (Proto): Initial sample to assess design/fit (~150−400+ per suit, highly variable). Based on tech pack.

Fit Sample: Adjusted after proto feedback (may be charged/non-charged).

Pre-Production Sample (PP Sample): Made with production materials, factory standard for confirmation before bulk. Cost often credited back against bulk order (subject to MOQ).